Fluitec AG is an innovative company counting to the top leaders of the world in the mixing and reaction technology using static mixing elements. CFD-calculations (Computed Fluid Dynamic) and especially developed specific software are used to characterize and to improve chemical processes.

Fluitec designs and produces a large variety of versatile mixing equipments which find a large use in many application fields: in addition to the examples here stated, you can find detailed information on the Fluitec website.

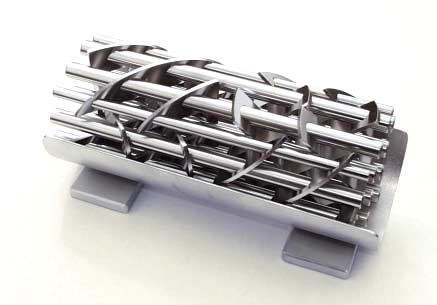

CSE-XR® Mixer / Heat Exchanger or Reactor

By combining static mixing elements with shell-and-tube heat exchangers, basic operations such as mixing, heat and mass transfer for chemical reactions are now possible even for highly viscous liquids. The excellent heat transfer performance and the high mixing efficiency of the CSE-XR® allows delicate operations also in laminar flow.

CSE-XR® Mixer / Heat Exchanger for food industry: its success is founded on the lack of any dead spots and its reliability for CIP cleaning (Cleaning In Place).

HD/CSE Mixer nozzles for injection molding: its typical feature is the low pressure drop at a high mixing efficiency.

CSE-X static mixers for extrusion: static mixers imply melts of a very homogeneous temperature profile. As a result, significant economies are possible due to the lower amounts of colorants or other additives.

Static Mixers CSE-X Micro/Macro: these mixers are particularly suitable for the fiber industry where a perfect homogenisation of the melt upstream the dies is essential;

Fluitec Small Bubbles Reactors (FSBR)are used for the high performance in-line gasification of

liquids of low viscosities. The generation of unique micro-bubbles at lowest energy consumption.

CSE-XR: the next generation

CSE-XR: the next generationDownloads